Self-Producing Factory-Professional Manufacturer

Jul 28,2022

What are the applications of snow removal roller brushes?

The snow removal roller brush of the snow sweeper can be equipped with a dust box and a spray dust removal mechanism according to user requirements.

Nov 12,2021

The production process of brush manufacturers

Brush manufacturers need to go through multiple processes to produce high-quality brushes. Below, I will briefly introduce the production process of brushes to you all:

Nov 12,2021

The note of the brush and its cleaning method?

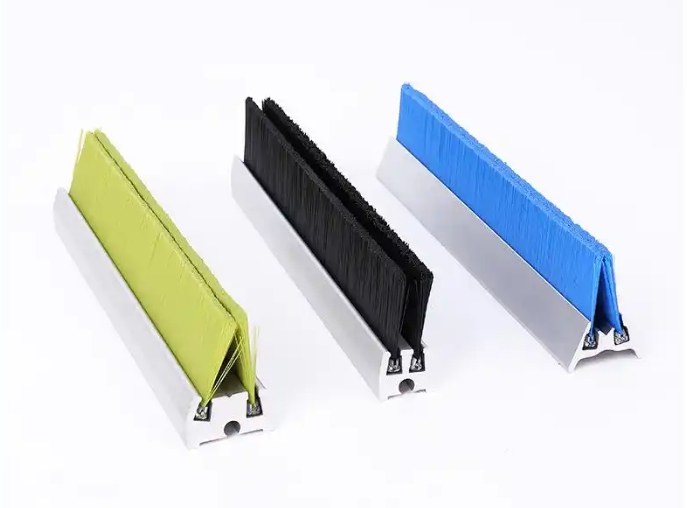

The strip brush is one of the industrial brushes, which can prevent dust from entering the interior of various doors and windows when in use. So, the note of the brush and its cleaning method? Next, we will talk about the small knowledge points related to him, hoping to bring help to more people.

Jan 10,2022

Cleaning brush manufacturers: about the role and scope of application of the brush

Cleaning brushManufacturer: The brush is also used more in life. The following describes the function and scope of application of the next brush. If you are also interested in this topic, let me introduce it to you. I hope you can bring some better help when you choose a brush.

Nov 12,2021

Fully disclosed: The production process flow of the filter tank brush!

According to the customer's requirements, select the matching wool. Put it into the automatic cutting machine and cut the bristles strictly according to the customer's bristle diameter. The bristle diameter must be strictly controlled within the tolerance range; otherwise, the bristles of the filter pool brushes produced will have inconsistent lengths. Generally, using automated machines to cut wool and filaments can not only greatly improve efficiency but also precisely control the tolerance within the specified range.

Nov 09,2021

With the rapid development of the industrial door sealing brush market, the chaos within the industry has gradually emerged. Data from the State Administration for Market Regulation shows that the nonconformity rate of sealing brushes reached as high as 32% in 2024, with the main issues focusing on inferior raw materials, rough manufacturing processes, and substandard adhesive backing. Therefore, mastering the five core indicators has become the key for dealers to accurately select high-quality products.

Contact Us

CEO: Alan

Email: alan@virostech.com

Phone: +86-15215693689

Sales Manager: Edith

Email: Edith@virostech.com

Phone: +86-15215693689