Self-Producing Factory-Professional Manufacturer

The production process of brush manufacturers

Nov 12,2021

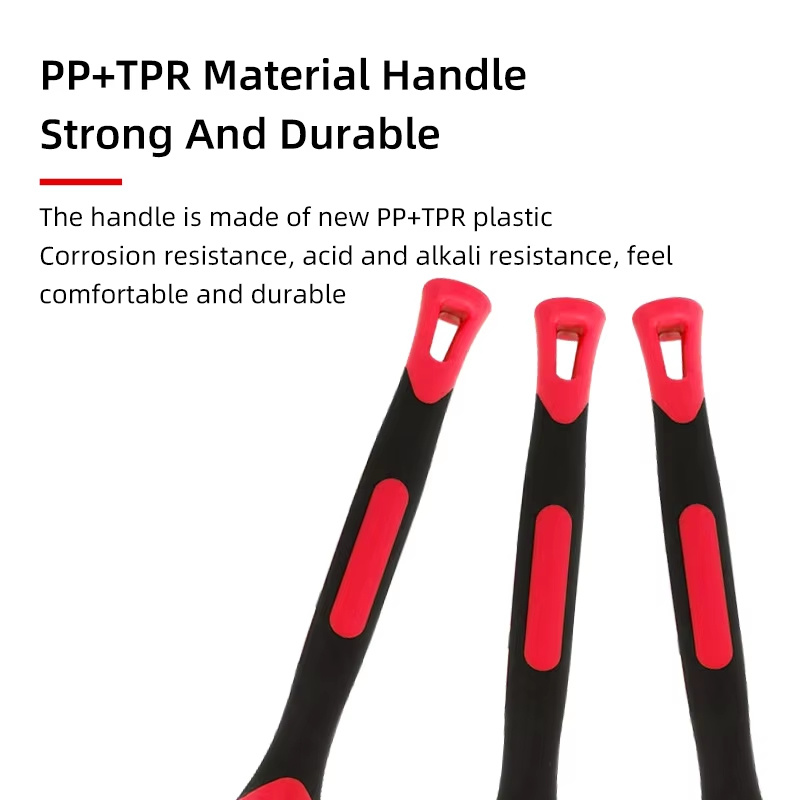

Brush manufacturers need to go through multiple processes to produce high-quality brushes. Below, I will briefly introduce the production process of brushes to you all:

Pulping:

Pulping is the process of converting various fibrous materials into a liquid of a certain concentration and adhesive properties. Commonly used ones include wood pulp, brown silk pulp and nylon latex, etc. According to different usage requirements, liquid materials of different raw materials can be selected to prepare the required liquid materials.

2. Impregnation:

The process of placing the impregnated blank under certain temperature conditions for a curing reaction to form a solid resin film layer with certain strength is called impregnation or fixation. The commonly used methods are the hot-melt method or the solvent method. The former is suitable for occasions where high-temperature curing is required; The latter is suitable for curing at room temperature.

3. Drying:

The method of taking the cured resin film layer out of the coating machine and then naturally drying it or heating and baking it to remove moisture is called drying (or dehydrating).

Hot Tags:

Contact Us

CEO: Alan

Email: alan@virostech.com

Phone: +86-15215693689

Sales Manager: Edith

Email: Edith@virostech.com

Phone: +86-15215693689

Lianxin Brush Industry

CEO : Alan

Sales Manager: Edith

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

REQUEST QUOTE

Please pay attention to your email.