Self-Producing Factory-Professional Manufacturer

Industrial Roller Brushes for Food Cleaning Machines

Nov 10,2025

Industrial food cleaning machine roller brushes are important tools designed for efficiently cleaning food materials. They are widely used to remove dirt, dust, and other debris from the surface of food products. The bristles of the rollers are made from various materials such as nylon, polypropylene, or steel, and can be customized to meet different cleaning requirements. The bristles agitate the surface of the materials to remove impurities, which are then rinsed, vacuumed, or swept away. In cleaning and conveying applications, the design of the roller brush is crucial to its performance. Factors such as bristle material and length, roller diameter and shape, as well as the speed and torque of the rotating parts, all play a role in determining how effectively the roller brush performs its intended function.

I. Structure of the Roller Brush

A roller brush typically consists of bristles, bearings, and a supporting frame — among which the bristles are the most critical component. Bristles are commonly made from synthetic materials such as nylon and polyester, or a blend of natural materials such as pig bristles, horsehair, or cow tail hair. These materials offer good elasticity and corrosion resistance. The bristles are bundled together, and their length and diameter are adjusted based on the application and the type of material being cleaned.

The bearing is the core part of the roller and its installation quality directly affects the brush’s performance and lifespan. Bearings are usually made of high-strength alloy steel, providing excellent axial and radial load-bearing capacity to withstand high speeds and heavy loads.

The supporting frame serves as the structural base for the roller brush and is often made from aluminum alloy or stainless steel, which ensures high corrosion resistance and mechanical strength. The design and manufacturing precision of the frame also influence the stability and service life of the roller brush.

II. Classification of Roller Brushes

Based on structure and application, roller brushes can be divided into the following types:

Cylindrical Roller Brush:

Composed of multiple layers of bristles arranged cylindrically, this type is commonly used for cleaning fruits and vegetables.

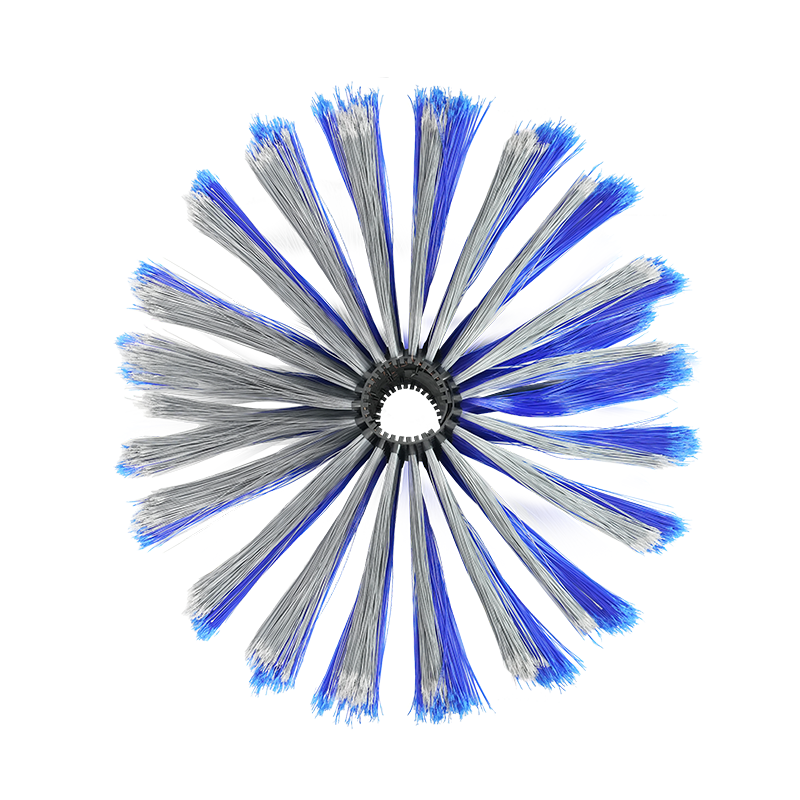

Disc Roller Brush:

Made up of multiple brush discs, it provides strong cleaning performance and large contact area, suitable for cleaning large food materials.

Rigid Roller Brush:

Constructed with metal bristles, it offers strong cleaning power and is used for scrubbing harder or tougher food materials.

Soft Roller Brush:

Made from soft materials such as silicone, it is ideal for cleaning delicate or easily damaged food materials.

III. Materials of the Roller Brush

The bristle materials used in roller brushes are generally divided into synthetic and natural types.

Synthetic bristles (e.g., nylon, polyester) have excellent corrosion resistance and elasticity, are easy to process and maintain.

Natural bristles (e.g., pig hair, horsehair, cow tail hair) provide good cleaning performance and biodegradability, but are more expensive and susceptible to moisture.

The bearings are typically made of high-strength alloy steel with good wear resistance and load capacity.

The frames are often made of aluminum alloy or stainless steel to ensure high corrosion resistance and durability.

IV. Manufacturing Methods

Roller brushes can be manufactured either by hand or by machine.

Handmade roller brushes are manually assembled by skilled workers, offering higher bristle quality and better cleaning performance, but production is time-consuming and more costly.

Machine-made roller brushes are automatically assembled, allowing for faster production, but the overall bristle quality and cleaning efficiency may be slightly lower than those of handmade brushes.

V. Applications

Roller brushes are widely used in cleaning and disinfecting fresh fruits and vegetables, agricultural products, seafood, condiments, and other food materials. They effectively remove surface impurities, microorganisms, and pesticide residues to ensure food safety and hygiene.

Beyond the food industry, roller brushes are also utilized in various industrial cleaning and dust removal processes, making them highly versatile and indispensable tools in both food processing and industrial applications.

Hot Tags:

Contact Us

CEO: Alan

Email: alan@virostech.com

Phone: +86-15215693689

Sales Manager: Edith

Email: Edith@virostech.com

Phone: +86-15215693689