Self-Producing Factory-Professional Manufacturer

Industrial Brush Manufacturer’s Guide to Choosing Strip Brushes

Nov 14,2025

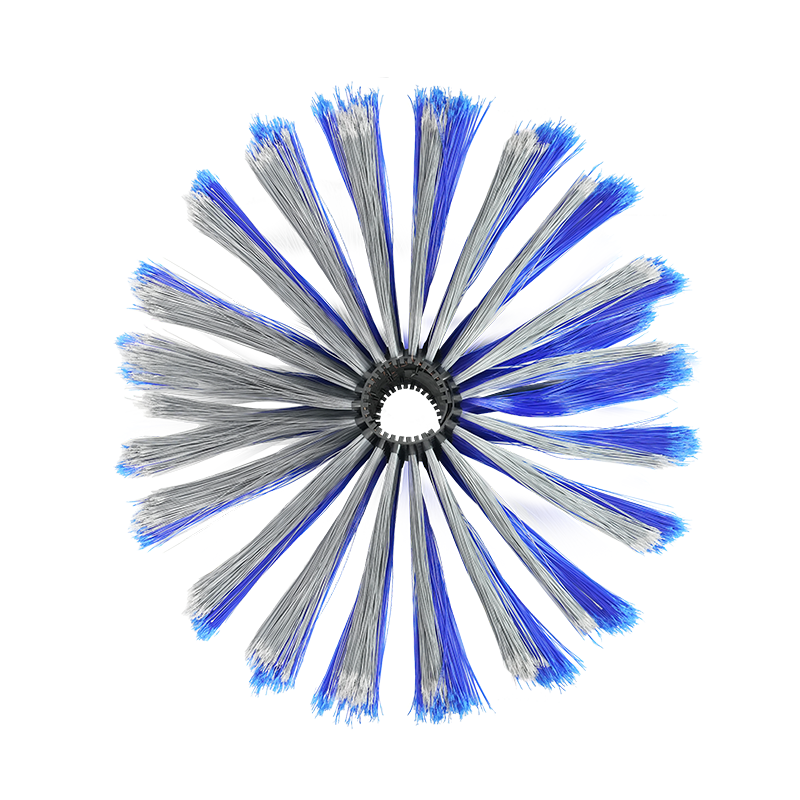

Strip brushes are commonly used in industrial applications such as cleaning, wiping, and debris removal. Their shape and material vary depending on specific purposes. Generally, the bristles of strip brushes are evenly distributed, though their length and diameter may not be uniform. Some applications require coarser bristle particles, making these brushes ideal for tackling extremely dirty or challenging areas.

How to Select Strip Brushes Material Selection

The material of strip brushes varies depending on the application scenario. When selecting, choose based on the material's characteristics. Common bristle materials include nylon, metal wire, graphite, hemp core, cow tail hair, and pig bristle.

Below are the characteristics of commonly used materials:

- Nylon Bristles: Nylon bristles offer extremely high abrasion resistance and corrosion resistance, and are relatively inexpensive. They are typically more suitable for wiping and cleaning scenarios.

- Metal Wire Bristles: Metal wires possess high hardness, enabling thorough removal of contaminants. However, these bristles are prone to rust, requiring careful handling before use.

- Graphite Bristles: Graphite bristles exhibit exceptional abrasion resistance and high-temperature performance. This makes them an excellent choice for specific scenarios, such as high-temperature cleaning or high-speed rotation applications.

- Hemp core bristles: Typically created by weaving hemp into the brush's center, this produces a mix of coarse and soft bristles, making the brush a versatile tool.

- Pig bristle bristles: Pig bristles offer excellent abrasion resistance and softness, making them a popular choice. However, it has limitations, such as being prone to breakage and trapping dirt, requiring careful consideration during selection.

- Bristle Length: The length of strip brush bristles is typically determined by application requirements. Different lengths yield varying effects: longer bristles better reach deep-seated grime, while shorter bristles suit cleaning smaller surfaces.

- Bristle Diameter: Bristle diameter affects the stiffness and strength of the strip brush, necessitating selection of an appropriate size for the task.

- Stiffness: Strip brush bristles require a certain degree of elasticity and stiffness. This allows the bristles to dynamically adjust their angle, depth, and direction during operation in response to varying stimuli, facilitating effective cleaning. Therefore, consideration must be given to selecting the appropriate bristle density and elasticity.

Selecting Models or Sizes Based on Application Scenarios

Due to varying industrial applications, strip brushes differ in dimensions, shapes, and number of strips. Certain scenarios requiring wear resistance, corrosion resistance, or high-temperature tolerance may demand higher quality standards. When purchasing strip brushes, pay attention to the application scenario and select the appropriate model or size based on requirements.Testing and Selecting Suitable ManufacturersAfter , ensure high-quality, reliable strip brushes by testing and selecting suitable manufacturers. Reputable brush manufacturers offer high-quality strip brushes and often provide post-purchase inspections to guarantee performance.

Application Scenarios for Strip Brushes

Cleaning Applications: Numerous industrial settings require cleaning to remove dirt or deposits, such as floor cleaning, vehicle surface cleaning, equipment cleaning, and pipeline cleaning. Selecting the right strip brush has become a common cleaning solution.Polishing Applications: Certain industrial processes require surface polishing, such as metal fabrication and woodworking. Selecting strip brushes with appropriate hardness and bristle density yields superior results.Optical Processing Applications: During optical manufacturing, strip brushes are used to remove debris, dust, and contaminants from surfaces prior to cleaning. Only thoroughly cleaned surfaces can achieve high-quality optical processing.

Hot Tags:

Contact Us

CEO: Alan

Email: alan@virostech.com

Phone: +86-15215693689

Sales Manager: Edith

Email: Edith@virostech.com

Phone: +86-15215693689