Self-Producing Factory-Professional Manufacturer

Industrial Brushes: The Essential Tool for Superior Surface Preparation

Nov 07,2025

Industrial Brushes: The Essential Tool for Superior Surface Preparation

Table of Contents

- 1. Introduction to Industrial Brushes

- 2. Types of Industrial Brushes for Surface Preparation

- 3. Applications of Industrial Brushes in Various Industries

- 4. Choosing the Right Industrial Brush for Your Project

- 5. Best Practices in Using Industrial Brushes for Surface Preparation

- 6. Maintenance and Care for Industrial Brushes

- 7. Innovations in Industrial Brush Technology

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

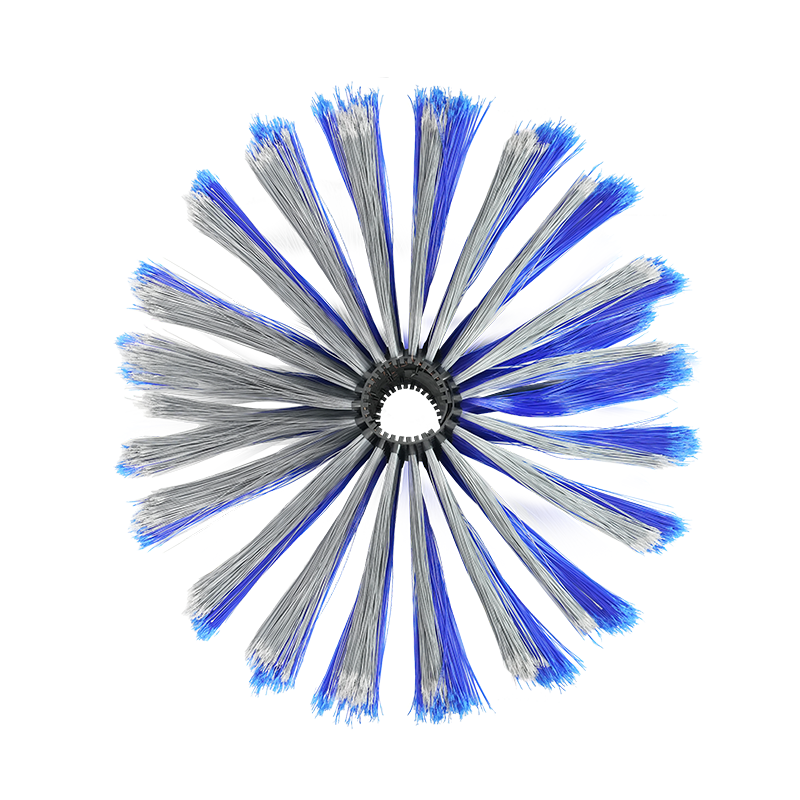

1. Introduction to Industrial Brushes

Industrial brushes play a **pivotal role** in surface preparation across various sectors, including manufacturing, construction, and automotive industries. These specialized tools are designed to clean, finish, and prepare surfaces prior to additional processing, such as coating or painting. Understanding the significance of these brushes is essential for achieving optimal surface quality and durability.

Surface preparation is often the most critical step in any finishing process. It ensures that surfaces are free of contaminants such as dust, grease, and old coatings that can compromise the integrity of the final product. Industrial brushes are engineered to meet these demands efficiently.

2. Types of Industrial Brushes for Surface Preparation

When it comes to industrial brushes, there is a diverse range of types, each designed for specific tasks. Here are some of the most common types used in surface preparation:

2.1 Wire Brushes

Wire brushes are ideal for heavy-duty cleaning, rust removal, and surface preparation of metals. They come in various shapes, including wheel, cup, and hand-held forms, making them versatile for different applications.

2.2 Nylon Brushes

Nylon brushes are more forgiving on surfaces compared to wire brushes. They are perfect for cleaning delicate surfaces and removing contaminants without damaging the underlying material. These brushes are often used in the automotive industry for cleaning engines and other intricate parts.

2.3 Abrasive Brushes

Abrasive brushes are designed with abrasive materials integrated into the bristles. They provide a higher level of cleaning and surface finishing, making them suitable for applications that require more aggressive cleaning.

2.4 Tube Brushes

Tube brushes are specially designed for cleaning inside tubes, pipes, and other hollow components. They are essential in various industries, including food processing and pharmaceuticals, where hygiene is paramount.

2.5 Specialty Brushes

Specialty brushes include a wide range of designs tailored for unique applications. Examples include brushes for cleaning delicate lenses, brushes for applying coatings, and brushes for specific manufacturing processes.

3. Applications of Industrial Brushes in Various Industries

The versatility of industrial brushes allows them to be used in a multitude of applications across different industries:

3.1 Automotive Industry

In the automotive industry, surface preparation is crucial for part assembly and painting. Industrial brushes are employed to clean surfaces of car frames and components, ensuring that paint adheres properly.

3.2 Manufacturing

Manufacturing facilities utilize industrial brushes for various tasks, such as deburring metal parts, cleaning molds, and preparing surfaces for welding. These processes require precision and efficiency, which industrial brushes can deliver.

3.3 Aerospace

In aerospace, the integrity of surfaces is critical. Industrial brushes help in cleaning and preparing components, ensuring they meet stringent safety and performance standards.

3.4 Construction

Construction sites often demand robust cleaning tools. Industrial brushes are used for preparing surfaces before applying coatings or sealants, ensuring long-lasting results.

3.5 Food Industry

In the food industry, sanitation is crucial. Industrial brushes are used to clean machinery and surfaces to prevent contamination, meeting health and safety regulations.

4. Choosing the Right Industrial Brush for Your Project

Selecting the right industrial brush is essential for achieving superior surface preparation. Consider the following factors when making your choice:

4.1 Surface Type

Different surfaces require different brush materials. Metal surfaces may benefit from wire brushes, while delicate surfaces may need nylon brushes.

4.2 Desired Finish

The type of finish desired will impact your choice of brush. For aggressive cleaning, abrasive brushes are ideal, while for a finer finish, softer brushes may be better suited.

4.4 Brush Shape and Size

The shape and size of the brush should match the application requirements. Larger brushes can cover more area, while smaller brushes provide precision for intricate tasks.

5. Best Practices in Using Industrial Brushes for Surface Preparation

To maximize the efficiency and lifespan of industrial brushes, follow these best practices:

5.1 Proper Technique

Using the right technique is vital. For example, when using a wire brush, work at a consistent angle and avoid excessive pressure to prevent damaging the bristles or the surface.

5.2 Regular Inspection

Inspect brushes regularly for wear and tear. A worn brush may not perform effectively, leading to subpar surface preparation.

5.3 Clean After Use

After each use, clean brushes to remove debris and contaminants. This practice helps maintain their effectiveness and prolongs their lifespan.

6. Maintenance and Care for Industrial Brushes

Proper maintenance is essential for ensuring the longevity and effectiveness of industrial brushes.

6.1 Cleaning

Regularly clean brushes to prevent build-up of materials. For wire brushes, a simple shake or tap can remove debris, while nylon brushes may require soap and water for thorough cleaning.

6.2 Storage

Store brushes in a clean, dry place away from direct sunlight and moisture. Proper storage prevents bristle deformation and rust development.

6.3 Replacement

Understand when to replace brushes. If performance declines or bristles become excessively worn, it’s time to invest in new brushes to ensure efficiency.

7. Innovations in Industrial Brush Technology

The brush manufacturing industry is continually evolving. Recent innovations include:

7.1 Advanced Materials

New materials, such as synthetic fibers and advanced alloys, are being used to enhance durability and performance, allowing brushes to withstand harsher conditions and extended use.

7.2 Eco-Friendly Options

With increasing environmental awareness, manufacturers are creating eco-friendly brushes made from sustainable materials. These options provide effective cleaning while minimizing environmental impact.

7.3 Automation Compatibility

Many industrial brushes are now designed to be compatible with automated systems, increasing efficiency and consistency in surface preparation processes.

8. Frequently Asked Questions (FAQs)

8.1 What is the primary purpose of industrial brushes?

Industrial brushes are used primarily for cleaning and preparing surfaces before further processing, such as painting or coating.

8.2 How do I know which brush to use for my application?

The choice of brush depends on the surface type, the desired finish, and the specific application requirements. Consult with a specialist if unsure.

8.3 Can industrial brushes be used on delicate surfaces?

Yes, nylon or softer brushes are suitable for cleaning delicate surfaces, reducing the risk of damage.

8.4 How often should I replace my industrial brushes?

Replace brushes when they show signs of wear, such as fraying bristles or diminished cleaning effectiveness.

8.5 Are there eco-friendly options for industrial brushes?

Yes, many manufacturers are now producing eco-friendly brushes made from sustainable materials that offer effective cleaning solutions.

9. Conclusion

In conclusion, industrial brushes are essential tools for achieving optimal surface preparation across various industries. By understanding the different types, applications, and best practices associated with these brushes, professionals can ensure superior results and extend the lifespan of their tools. As innovations continue to shape the landscape of brush technology, staying informed will be crucial for maintaining efficiency and quality in surface preparation tasks. Investing in the right industrial brushes not only enhances the quality of work but also contributes to the success of projects across various sectors.

Hot Tags:

Contact Us

CEO: Alan

Email: alan@virostech.com

Phone: +86-15215693689

Sales Manager: Edith

Email: Edith@virostech.com

Phone: +86-15215693689