Self-Producing Factory-Professional Manufacturer

The Art of Choosing the Right Industrial Brush for Your Machinery

Oct 03,2025

The Art of Choosing the Right Industrial Brush for Your Machinery

Table of Contents

- Understanding Industrial Brushes

- Types of Industrial Brushes

- Materials Used in Industrial Brushes

- Applications of Industrial Brushes

- Choosing the Right Industrial Brush

- Maintenance and Care for Industrial Brushes

- Common Mistakes When Choosing Brushes

- Frequently Asked Questions

Understanding Industrial Brushes

Industrial brushes are crucial tools in various manufacturing and processing environments. Their primary function is to clean, polish, apply, or remove materials from surfaces. Selecting the appropriate brush can significantly influence the efficiency and effectiveness of machinery operations. Understanding the different types of brushes and their specific applications is essential for optimal performance.

Types of Industrial Brushes

Industrial brushes come in various designs, each tailored to specific tasks. Here are some common types:

1. Cylinder Brushes

Cylinder brushes offer a 360-degree brushing surface, making them ideal for cleaning cylindrical objects. They are often used in automotive manufacturing and packaging industries.

2. Disc Brushes

Disc brushes feature a flat surface and are perfect for scrubbing or polishing flat surfaces. Their versatility makes them suitable for use in woodworking, metalworking, and various other applications.

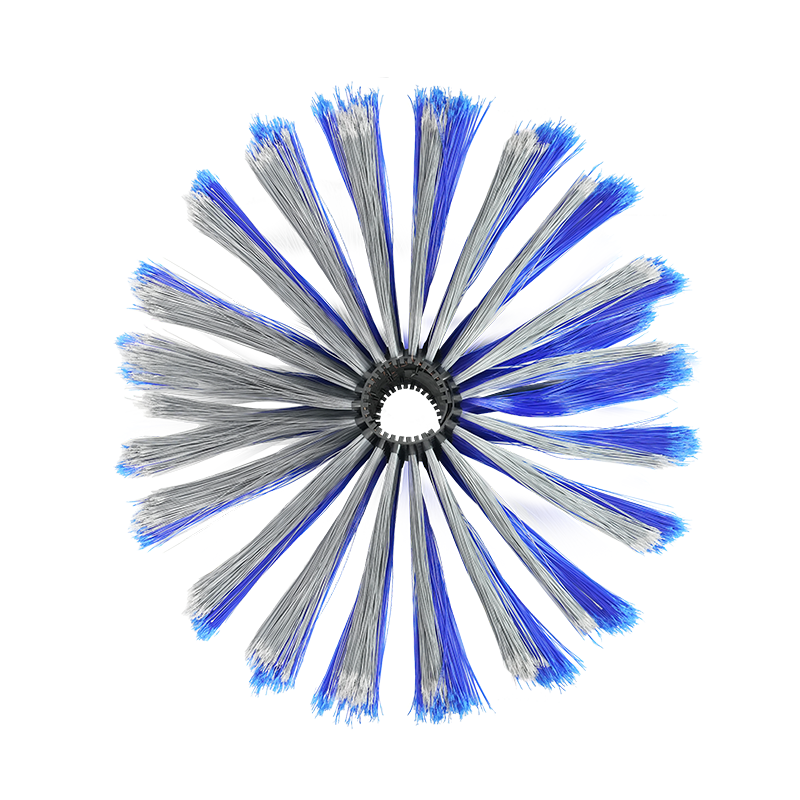

3. Wheel Brushes

Wheel brushes are designed for edge cleaning and contouring. They can easily access hard-to-reach areas, making them essential in detailed cleaning processes.

4. Hand Brushes

Hand brushes allow for manual application and precision work. These are often utilized in maintenance tasks and light-duty cleaning.

5. Specialty Brushes

Specialty brushes are custom-designed for specific applications. They can include features like chemical resistance, unique bristle configurations, or specialized shapes for intricate tasks.

Materials Used in Industrial Brushes

The performance and durability of industrial brushes largely depend on the materials used in their construction. Various bristle materials cater to different applications:

1. Natural Bristles

Natural bristles, such as those made from animal hair, offer excellent flexibility and are often used for delicate tasks. They are ideal for applications requiring a gentle touch.

2. Synthetic Bristles

Synthetic bristles, made from materials like nylon or polyester, are durable and resistant to wear and chemicals. They are commonly used in heavy-duty cleaning applications.

3. Wire Bristles

Wire bristles, often made from steel or brass, are highly effective for aggressive scrubbing and removal of rust or paint. However, they can be abrasive and are best used on tough surfaces.

Applications of Industrial Brushes

Understanding the applications of different types of brushes helps in making informed choices tailored to your specific machinery needs:

1. Surface Preparation

Industrial brushes are essential in preparing surfaces for painting or coating. They help remove contaminants and ensure proper adhesion.

2. Cleaning and Maintenance

Regular cleaning of machinery using the appropriate brush prevents buildup and prolongs equipment life. Brushes can efficiently clean intricate components that are hard to reach.

3. Polishing and Finishing

Using the right brush for polishing can significantly enhance the finish of materials, making them more aesthetically pleasing and smoother.

4. Material Application

Some brushes are specifically designed to apply coatings, adhesives, or lubricants evenly across surfaces.

Choosing the Right Industrial Brush

Selecting the correct brush for your machinery is a critical decision that impacts productivity and efficiency. Here are essential criteria to consider:

1. Identify the Task

Begin by understanding the specific task the brush will perform. Consider factors like the type of surface, the level of cleaning required, and whether the brush will be used for application or removal.

2. Assess the Material

Choose a brush material that complements the task and the surfaces you’re working with. For instance, wire brushes for tough cleaning tasks versus softer bristles for delicate surfaces.

3. Evaluate Size and Shape

The size and shape of the brush should match the area it intends to clean or apply material to. Ensure that it can easily reach and effectively cover the designated area.

4. Consider Durability

Select brushes that can withstand the rigors of their intended application without degrading quickly. Look for high-quality materials that ensure longevity.

5. Look for Compatibility

Ensure that the brush is compatible with the machinery and equipment you are using. This includes verifying the brush's attachment method and ensuring it fits appropriately.

Maintenance and Care for Industrial Brushes

Proper maintenance and care for your industrial brushes not only extend their lifespan but also maintain the quality of their performance. Follow these tips for optimal care:

1. Regular Cleaning

After each use, clean brushes to remove any debris or residues. This prevents contamination of surfaces and maintains the brush's effectiveness.

2. Proper Storage

Store brushes in a dry place where they are protected from moisture and extreme temperatures. Avoid placing heavy objects on top of brushes to prevent deformation.

3. Inspect for Damage

Regularly inspect brushes for signs of wear and tear. Replace them as necessary to ensure optimal performance during your operations.

4. Follow Manufacturer Guidelines

Always refer to the manufacturer's care instructions to understand the best practices for cleaning and maintaining specific brush types.

Common Mistakes When Choosing Brushes

Navigating the vast options can lead to some common errors. Avoid these pitfalls to ensure effective brush selection:

1. Ignoring Surface Compatibility

Using the wrong brush type on a surface can result in damage or inadequate cleaning. Always consider the surface material before selecting a brush.

2. Overlooking Brush Size

Choosing a brush that is too large or too small for the task can hinder efficiency and effectiveness. Ensure the size matches the area of application.

3. Neglecting Maintenance Needs

Selecting brushes without considering their maintenance requirements can lead to increased costs and decreased performance. Understand how to care for your brushes.

4. Failing to Test

Don’t hesitate to test brushes on a small area before full application. This helps ensure they’re suitable for your needs without risking damage.

Frequently Asked Questions

1. What is the best material for industrial brushes?

The best material depends on the specific application. Synthetic bristles are great for durability, while natural bristles are ideal for delicate tasks.

2. How often should I replace my industrial brushes?

Brushes should be replaced when they show significant wear or damage. Regularly inspect them to determine when replacement is necessary.

3. Can I use the same brush for different applications?

It’s generally advisable to use specific brushes for designated tasks to prevent cross-contamination and ensure optimal cleaning or application performance.

4. How do I clean my industrial brushes?

Clean brushes by removing debris and rinsing them with water. For stubborn residues, mild detergents may be used, but avoid harsh chemicals that could damage the bristles.

5. What factors should I consider when choosing an industrial brush?

Consider the task, material compatibility, size and shape, durability, and compatibility with your machinery when selecting an industrial brush.

Conclusion

Choosing the right industrial brush for your machinery is essential for maintaining operational efficiency and achieving the best results in your manufacturing processes. By understanding the different types of brushes, their applications, and maintenance needs, you can make informed decisions that enhance productivity. Remember to evaluate the specific criteria outlined herein to ensure the brush you choose aligns perfectly with your requirements. With careful consideration, you can master the art of brush selection, ensuring your machinery operates at its peak performance for years to come.

Hot Tags:

Contact Us

CEO: Alan

Email: alan@virostech.com

Phone: +86-15215693689

Sales Manager: Edith

Email: Edith@virostech.com

Phone: +86-15215693689