Self-Producing Factory-Professional Manufacturer

How Industrial Brushes Can Enhance Production Line Efficiency: A Comprehensive Guide

Sep 29,2025

How Industrial Brushes Can Improve Your Production Line Efficiency

Table of Contents

- Introduction to Industrial Brushes

- Types of Industrial Brushes

- Applications of Industrial Brushes

- Benefits of Using Industrial Brushes in Manufacturing

- Improving Production Line Efficiency with Industrial Brushes

- Maintenance Tips for Industrial Brushes

- Case Studies: Success Stories

- Frequently Asked Questions (FAQs)

- Conclusion

Introduction to Industrial Brushes

In the realm of manufacturing, efficiency is paramount. Every element of the production process must operate smoothly to maximize output and minimize waste. One often-overlooked component that plays a vital role in this equation is the industrial brush. These tools are not merely for cleaning; they serve various purposes that can significantly enhance production line efficiency.

Industrial brushes come in a variety of shapes and sizes, each designed for specific applications. By understanding what industrial brushes can bring to your production line, you can make informed decisions that lead to improved efficiency, lower costs, and ultimately a better bottom line.

Types of Industrial Brushes

Before delving into the benefits and applications of industrial brushes, it is essential to understand the different types available. Each type serves unique functions and is suited for various tasks.

1. Wire Brushes

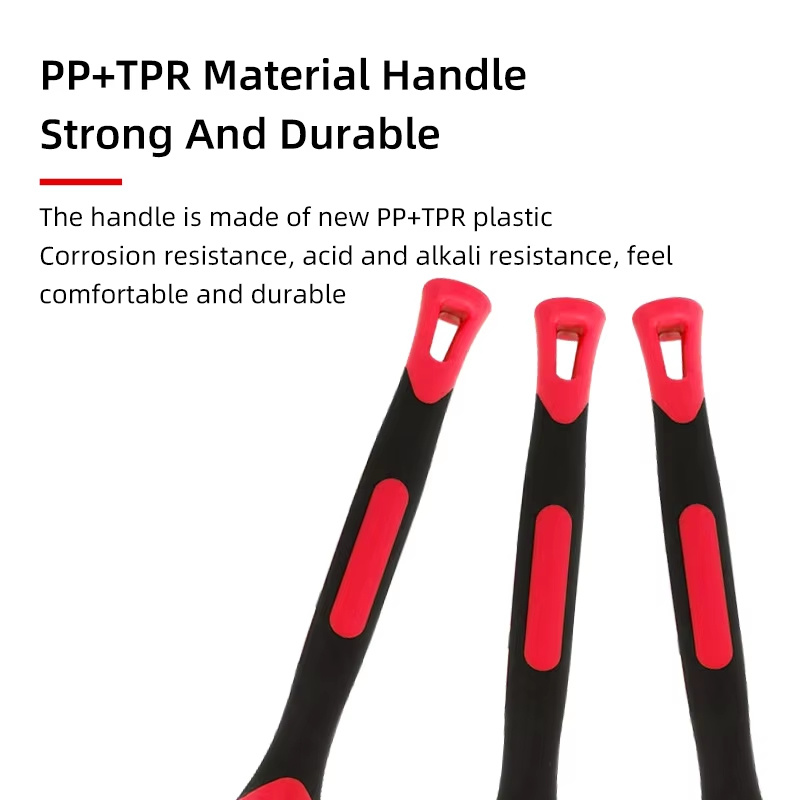

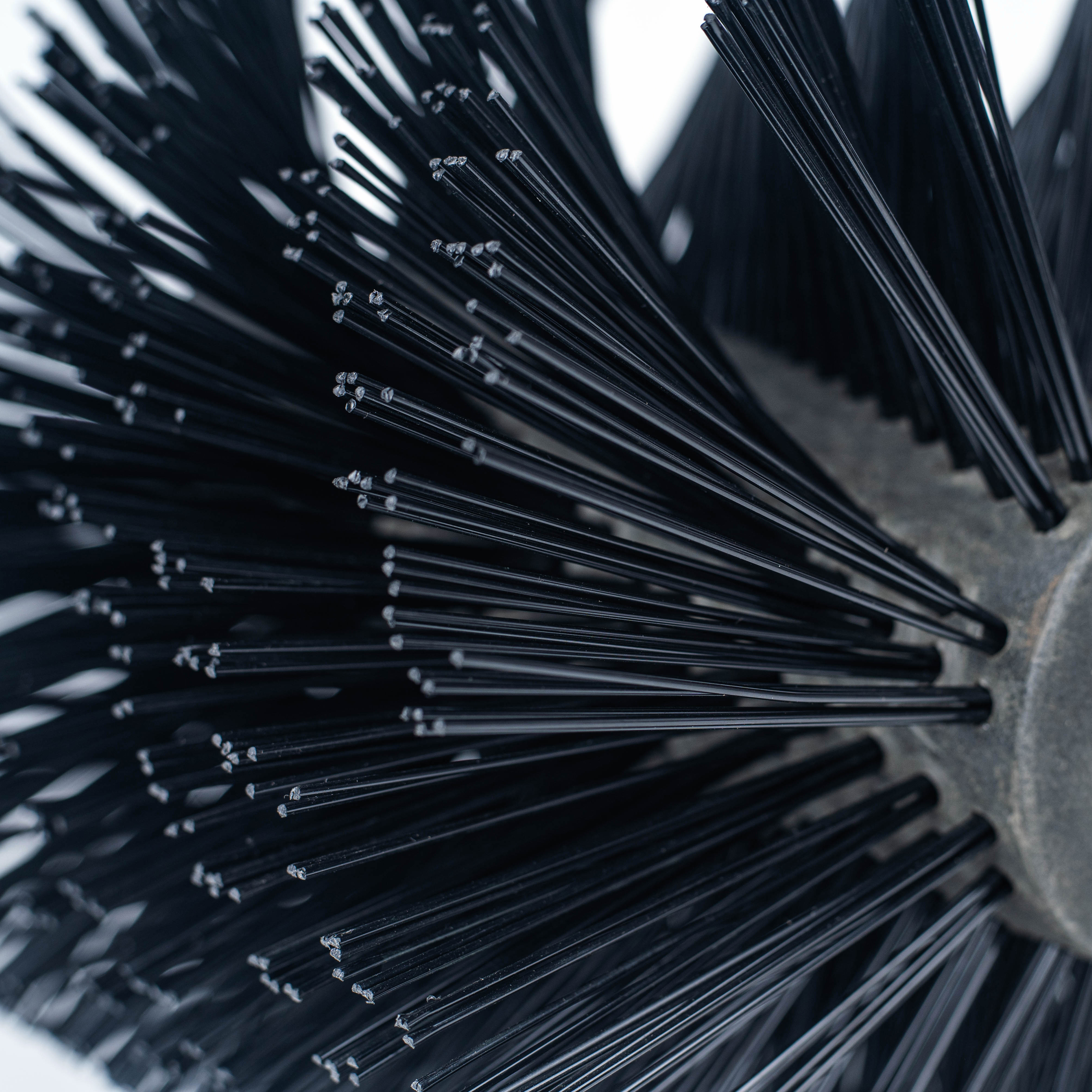

Wire brushes are often used for heavy-duty cleaning and surface preparation. They are capable of removing rust, paint, and other contaminants from metal surfaces. Wire brushes are available in both manual and power-driven forms, making them versatile for different applications.

2. Nylon Brushes

Nylon brushes are softer and ideal for less aggressive tasks. They can be used for delicate cleaning or polishing without damaging surfaces. These brushes are commonly used in the automotive and electronics industries.

3. Polypropylene Brushes

Polypropylene brushes are resistant to chemicals and moisture, making them suitable for harsh environments. They are commonly used in food processing and pharmaceutical applications where hygiene is critical.

4. Specialty Brushes

Specialty brushes are designed for unique tasks, such as deburring or polishing intricate components. These brushes can be custom-made to fit specific applications, ensuring optimal performance.

Applications of Industrial Brushes

Industrial brushes find their applications across various sectors, including automotive, aerospace, food processing, and more. Here are some key areas where industrial brushes play a crucial role:

1. Surface Preparation

Before painting or coating a surface, it is essential to prepare the surface adequately. Wire brushes can remove contaminants, ensuring better adhesion for paints and coatings.

2. Cleaning and Maintenance

Regular cleaning of machinery and equipment is vital for maintaining efficiency. Industrial brushes can help remove debris, dust, and contaminants, prolonging the life of equipment and ensuring smooth operation.

3. Deburring and Finishing

After manufacturing, components often have sharp edges that require deburring. Specialty brushes can smooth these edges, ensuring safer handling and improved aesthetics of the final product.

4. Polishing and Buffing

For applications requiring a polished finish, nylon brushes can create a shiny surface without scratching. This is particularly important in industries where appearance matters, such as luxury goods and consumer electronics.

Benefits of Using Industrial Brushes in Manufacturing

Utilizing industrial brushes in your production line can yield numerous benefits. Here are some key advantages:

1. Increased Efficiency

Industrial brushes can significantly improve workflow by enhancing cleaning and maintenance processes. This leads to less downtime and increased productivity.

2. Cost Savings

By preventing wear and tear on machinery and reducing the need for extensive manual labor, industrial brushes can help lower operational costs. The initial investment in brushes often pays off quickly.

3. Versatility

With a variety of types available, industrial brushes can be employed in multiple applications across different industries. This versatility enhances their value in a manufacturing setting.

4. Improved Product Quality

Using the right brush for the right application can enhance product quality. Proper surface preparation and finishing lead to better adhesion of coatings and a more polished appearance.

Improving Production Line Efficiency with Industrial Brushes

To truly harness the potential of industrial brushes for improving production line efficiency, consider the following strategies:

1. Assess Your Needs

Evaluate your current production processes to identify areas where brushes can enhance efficiency. Whether it's cleaning, deburring, or polishing, understanding your specific needs will guide your brush selection.

2. Invest in Quality

Not all brushes are created equal. Investing in high-quality industrial brushes ensures they last longer and perform better, ultimately leading to enhanced efficiency.

3. Train Your Staff

Proper training for staff on how to use and maintain industrial brushes can prevent misuse that leads to inefficiencies. Understanding the correct applications and techniques will maximize the benefits of these tools.

4. Monitor Performance

Regularly monitor the performance of industrial brushes in your production line. Tracking their impact on efficiency and productivity will help in making informed decisions regarding future investments.

Maintenance Tips for Industrial Brushes

To maintain the effectiveness of industrial brushes, regular maintenance is essential. Here are some tips to keep your brushes in top condition:

1. Clean Brushes Regularly

After each use, clean brushes to remove debris and contaminants. This will extend their lifespan and ensure optimal performance.

2. Inspect for Wear and Damage

Regularly check brushes for signs of wear or damage. Replace any that show significant wear to maintain efficiency in your production line.

3. Store Properly

Store brushes in a dry, cool place to prevent damage from moisture or heat. Proper storage will help maintain their structure and usability.

4. Follow Manufacturer Guidelines

Always follow the manufacturer's recommendations for use and maintenance. This will ensure you get the most out of your industrial brushes.

Case Studies: Success Stories

Examining real-world applications of industrial brushes can illustrate their impact on production efficiency:

1. Automotive Industry

A leading automotive manufacturer implemented wire brushes for surface preparation before painting. This change reduced paint defects by 30%, resulting in significant cost savings and improved customer satisfaction.

2. Food Processing

In a food processing plant, polypropylene brushes were introduced for cleaning equipment. This led to compliance with health regulations and a 25% decrease in cleaning time, allowing for more production runs.

3. Aerospace Manufacturing

An aerospace company utilized specialty brushes for deburring. This improved the quality of their components, leading to higher safety standards and reduced rework costs by 15%.

Frequently Asked Questions (FAQs)

1. What are the main types of industrial brushes?

The main types of industrial brushes include wire brushes, nylon brushes, polypropylene brushes, and specialty brushes, each designed for specific applications.

2. How do industrial brushes improve efficiency?

Industrial brushes enhance efficiency by streamlining cleaning processes, improving surface preparation, and reducing downtime caused by equipment maintenance.

3. Can industrial brushes be customized?

Yes, many manufacturers offer custom industrial brushes tailored to specific applications and requirements, ensuring optimal performance.

4. What industries benefit from using industrial brushes?

Industries such as automotive, aerospace, food processing, and electronics benefit significantly from using industrial brushes.

5. How often should I replace my industrial brushes?

The lifespan of industrial brushes depends on usage and wear. Regular inspections will help determine when a brush needs replacement to maintain efficiency.

Conclusion

Incorporating industrial brushes into your production line can yield substantial efficiency gains. By understanding the various types, applications, and maintenance practices associated with industrial brushes, manufacturers can enhance their productivity and product quality. As industries continue to evolve, leveraging the power of these tools will be essential for staying competitive and achieving operational excellence.

Hot Tags:

PREVIOUS:

Contact Us

CEO: Alan

Email: alan@virostech.com

Phone: +86-15215693689

Sales Manager: Edith

Email: Edith@virostech.com

Phone: +86-15215693689